Industry 4.0 for Supply Chain – The role of AI (Part 2)

This is part 2 of a 3-part blog, addressing the 3 questions below.

Part 1 – What is Industry 4.0?

Part 2 – Where does Supply Chain figure in Industry 4.0?

Part 3 – What is the role of AI in Supply Chain for Industry 4.0?

You can find Part 1 here.

How does Industry 4.0 influence Supply Chains?

Industry 4.0 and the Internet of Everything (another name for IoT), bring a connected world into play. The benefits to be reaped are possible precisely because they are all connected. To elaborate this let us look at an example.

The car manufacturer Toyota has established just-in-time manufacturing practices. The inventory levels of car parts that they hold have shrunk to accommodate these practices. The assembly line gets parts from Toyota plants and from their ecosystem of suppliers. Toyota conveys their need for inventory at a detailed level to their suppliers who deliver just in time. This brings down costs dramatically for Toyota. In a connected world any change in the production plan at Toyota will be automatically notified to the supplier, who in turn can ramp up or ramp down their production. Such plan changes can be in turn notified to their suppliers who can act on this information. The flow of information can traverse the entire supply chain and can result in business decisions being made in the best interest of each of the parties involved.

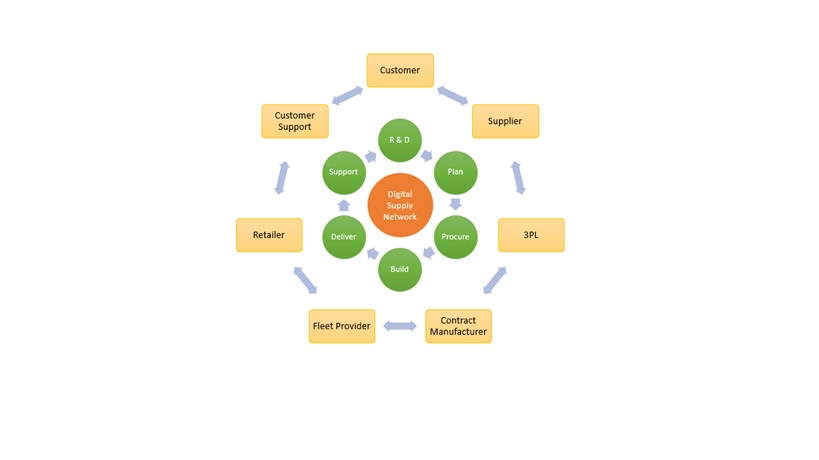

Digital Supply Networks

Digital Supply Networks are the supply chain networks of the future. They are characterized by being connected / digital. They are real time networks that offer online access to services, as well as visibility in the execution. They can offer scheduled as well as on demand services and can respond to demand stimuli to fine tune the supply. Let us see what all that jargon translates to with an example.

An interior designer is furnishing an office space and places an order on an ecommerce portal for specialized lighting equipment. The order includes customization such as color and style of casing and printing of the company logo on the casing. The customer has chosen to pay a premium for quick delivery. The placement of the order triggers a chain of events that flow through the digital supply chain. The factory gets a “priority” order that is scheduled for production. The required quantity of casing for that order is not available in stock, automatically creating a shortage alert. The system places an “expedited delivery” order to cover the shortage and also ensure recommended minimum inventory level for that type of casing. A forecasting model ingests data for this order, as well as the stock shortage to fine tune the minimum inventory level for the casing.

The casing supplier places an “on demand” order on his transportation partner to deliver the casings from ready inventory to their customer. The transportation partner is an aggregator who allocates a truck based on proximity, vehicle type and other business factors. The casing supplier also starts a production run to replenish his ready inventory. His production system places an order for raw material on their supplier. A smart contract raises an invoice on the factory as per payment terms for “expedited delivery”. The contract settlement triggers are sent to finance departments.

The factory which is now producing the lighting equipment also schedules a delivery of the finished product to the e-commerce portal’s designated cross dock. Their fleet provider who has a set of trucks works out an optimal fleet plan for the day based on orders on hand. The factory is informed of an ETA for the truck to pick up the goods. Alternately the factory can specify an expected time that the fleet provider can factor.

When the products are ready, the orders are delivered by the ecommerce company to the customer within the guaranteed time. The number of business that come into play to make this happen are numerous and they constitute the digital supply network. These businesses are connected and can send each other real time updates as well as service requests or orders. The businesses themselves are dynamic and align/realign the execution to incoming orders.

Digital Supply Networks are built using ecosystems and providers who can be tapped on need basis. These businesses are able to talk to each other digitally, thanks to APIs that allow integration. Services can be ordered, status can be tracked, alerts are pushed and the provider is truly online and real time. Some exciting technology such as smart contracts and blockchain are ushering in the potential to work with even new providers in a trusted manner.

Each link the supply chain has to learn how to be real-time and dynamic in their business to leverage an ecosystem that can save costs as well as increase service levels dramatically. Retail shops, distribution warehouses, ecommerce cross docks, manufacturing units, fleet providers, aggregators, truck owners, finance departments, ports, banks and financial institutions, trusted platforms will all be part of this digital supply chain that is a living breathing organism which will respond to customer demand. Exciting times ahead.

In the next part we will look at how Artificial Intelligence plays a role in digital supply networks.