Cold Chain Operations – A Systems Perspective

What are Cold Chain Operations?

Cold Chain Warehouse Operations are typically related to storage of materials within cold storage. This includes Edible Products like Meat, Poultry, Sea Food, Vegetables & Fruits, Frozen Foods like Ice Creams & Yogurts, Packaged Products like Frozen Peas & Corn, Pharmaceutical Products like Vaccines etc.,. Each Product has its optimal temperature for storage and Warehouse Zones with specific temperature zones are established for storage of each such item.

Generally Cold Chain Warehouses will have the following zones:

- Ambient Temperature Zones

- Chilled Temperature Zones

- Specific Temperature Zones

Material passes through the Ambient Temperature Zones during the loading and unloading operations. It is important that all material is kept in this area for just about the absolutely minimum unavoidable time as material quality can degrade fast while in the ambient temperature zones. The chilled zones are the Receiving and Dispatch Bays which are common for all goods coming in or out of the warehouse. Obviously such common zones cannot be at the optimum temperature for all the products handled in the warehouse; hence a chilled temperature is maintained here. Counting of Stock received, Palletisation, Labelling etc., activities are carried out here after which the products are moved to their respective Specific Temperature Zone. It may be noted that if material entering the cold storage warehouse is palletised and labelled at source (rather than at the warehouse), significant time savings can be achieved while the product is being received. Likewise, if Product dispatches are made in units of full pallets (rather than individual packages and cartons), similar time savings can be realized at the time of dispatch. Such measures can minimize the time spent on a product outside its Specific Temperature Zone and increase the overall life of the Product.

IT Considerations for Cold Storage Warehouses

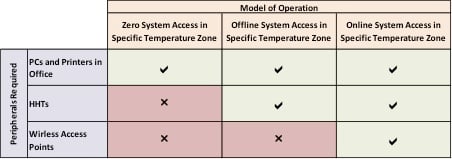

Like any scalable business operation, Cold Chains also require IT systems to manage the daily operations. Warehouse Management Systems are critical for the same. However Cold Storage environment can be very harsh for the IT peripherals like Hand Held Terminals, Wireless Access Points etc., and hence specific hardware for such temperature ranges will need to be procured. As Specific Temperature Zones have thick insulated walls, signals from Wireless Access Points maintained outside such zones may not reach within the Specific Temperature Zones. Hence Wireless Access Points for the Specific Temperature Zones will need to be installed. IT Budget can be significantly impacted by the cost of such peripherals.

Depending upon the overall IT budget any one of the following type of operations can be opted for the Warehouse Management System:

- Zero System Access within Specific Temperature Zones

- Offline System Access within Specific Temperature Zones

- Online System Access within Specific Temperature Zones

Each of the Operations are explained below:

- Zero System Access within Specific Temperature ZonesIn this method of operations, System Access is not available within the Specific Temperature Zones. This reduces the cost of peripherals significantly. Put-away Instructions generated by the system are printed out and the put-away is performed accordingly. Locations where actual put-away is performed in the warehouse (in case different from the suggested location in the instruction) is noted down in the paper and brought back to the Warehouse office. The results of put-away are then updated to the system. Likewise, the Picking Instruction is also printed out and the warehouse personnel perform the Pick accordingly. In case stock is picked from a location or batch which is different from what is suggested in the instruction, the same is recorded in the paper and brought back to the Warehouse office for posting into the system.Such a system reduces the Total Cost of Ownership (TCO) of the system significantly and improves the ROI. However on the flip side, transactions are posted in the system based on the updates provided by the personnel and such transactions can be erroneous to that extent. Barcode scans of locations performed within the Specific Temperature Zones provide a much higher accuracy but this is not possible in this model of operation. An important KPI of Cold Chain operations is how less a product is maintained outside its Specific Temperature Zone. Bar Code scans can accurately determine when a product was outside or within the Specific Temperature Zones and makes computation of this KPI possible, but again this is not possible in this model of operation. We shall explore barcode scanning based operations in the subsequent sections.

- Offline System Access within Specific Temperature ZonesOffline System Access implies that required data is downloaded locally to Handheld Terminal Devices. Transactions within Specific Temperature Zones are then carried out locally on the Handheld Terminal Devices. So instead of recording the alternate put-away locations on paper, in this model of operation the warehouse personnel records the same by scanning the bar coded location numbers. This improves the accuracy of the Location & Batch wise Stock in the warehouse and thereby improves the overall reliability of FIFO / FEFO / FMFO based operations. Timestamp of scans is also captured and thereby exact estimation of time spent outside of Specific Temperature Zones can also be reliably computed. Data recorded in Handheld Terminals within the Specific Temperature Zones is synchronized to the WMS Server at the end of operations. In this model of working, the cost of HHT Devices (suitable for working under low temperatures) gets added. Cost of Wireless Access Points within Specific Temperature Zones is avoided as the operations within such zones are carried out in an offline manner.Such operations are a good balance between Cost and Efficient Warehouse Operations. But there are a few cons which may also be noted. The real-time updation of system is not achieved here and the picture of inventory can be wrong to that extent. Inventory positions are updated only when the HHT Transactions are synchronized back to the System. Offline Transaction Synchronization has its own complications. Incorrect Batch or Location scans carried out inside the Specific Temperature Zones get validated only at the time of synchronization and this can create synchronization conflicts which will have to be corrected manually. Resolving such conflicts can be quite cumbersome. These problems are avoided by opting for an online system access which we shall now see.

- Online System Access within Specific Temperature ZonesIn this model, the warehouse personnel are always connected to the WMS – even while they are in the Specific Temperature Zones. There is no requirement of downloading data locally to HHTs, and operations are performed online. Real time validations are carried out on all scans performed within the Specific Temperature Zones and inventory is also updated as transactions are executed in the warehouse. Synchronization conflicts are avoided. This is by far the cleanest and most accurate & reliable model of conducting operations. However the cost overheads of such operations must be weighed in before opting for the same. Such operations require availability of Wi-Fi signal within the Specific Temperature Zones and hence the cost of Wireless Access Points of suitable operating temperatures will need to be taken into consideration.The following matrix summarizes the requirement of peripherals in each model:

Other Considerations

System Interfaces:

Cross System Integration are crucial to any system. In case of 3PL providers this gets all the more complicated as integrations are required with numerous systems belonging to various Principals. WMS Systems providing standard API access can help in streamlining the interfaces and minimizing the maintenance overheads of the systems.

Hardware Interfaces

Apart from the above, hardware interfaces to Temperature Sensors are also required to generate system wide alert for abnormalities in temperature in the Specific Temperature Zones. Exact method of such integration will depend on the make & model of the sensors and its specific alerting mechanisms.

Labelling

If at all Barcode Labelling of Products is to be carried out within the Cold Chain operations, cost of label stationary must be taken into account. Depending upon the temperature ranges special labels will be required to avoid the smudging and degradation of the label while moving in and out of low temperature zones.

Summary

Cold Chain operations are essential for increasing the life of perishables. In fact in a large country like India they are central to reducing food wastage across the country. IT Systems in large scale Cold Chains are required for maintaining smooth operations. A clear IT Budget for such systems will help in identifying and finalizing from one of the models of operations listed here. Profitability of operations is key to any business, and hence trade-offs between various pros and cons of the models listed here need to be examined and a decision taken accordingly.